Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Effect of Admixtures on Concrete and Superplasticizers on Cementitious Material

Authors: Mehak Bashir, Zafira Nazir, Sharafoun Nisa, Sana Hameed, Sabree Ashraf, Snowber Yousuf

DOI Link: https://doi.org/10.22214/ijraset.2021.39230

Certificate: View Certificate

Abstract

Use of chemical and mineral admixtures have proved beneficial in improving quality, workability and have enhanced finish ability of concrete. They also help in maintaining the concrete during its important stages such as mixing, transporting, placing, curing and also in adverse weather conditions. Superplasticizers are super water reducers that allow 15-20% water reducion thereby increasing the workability without any change in the composition of mix.The reduction in water and cement reduces creep, shrinkage and heat of hydration. In this paper effect of different chemical and mineral admixture was studied along with sand to aggregate volume ratio ,cement content and water were analysed by preparing different concrete mixtures using water reducers and superplasticizers. A specimen of 200mm and 300mm was prepared and tested for compressive strength, split tensile strength and young\\\'s modulus. Slump test was also performed at 15 min interval. Also superplasticizers (TJ III , LIGNIN-SULPHONATE-based and NAPHTHALENE-SULPHONATE-based) were taken and their effect on the heat of hydration and induction period of cementitious material (portland cement) was studied.

Introduction

I. INTRODUCTION

History of Admixtures is as old as the history of concrete .Blood , pig fat( lard ) & milk was used by Romans to achieve better workability. An ADMIXTURE is a material other than water , aggregates , cementitious materials and fiber reinforcement used as an ingredient of a cementitious mixture to modify its freshly mixed ,setting or hardened properties and that is added to the batch before or during its mixing.Water reducers are special chemical products added to a concrete mixutre which reduce the water content by 5-10%. By reducing the amount of water , the cement paste will have higher density , which results in higher paste quality which inturn yields higher compressive and flexural strength , lower permeability , increase resistance to weathering , improve the bond of concrete and reinforcement , reduce the volume change from drying and wetting and reduce shrinkage cracking tendencies(PCA,1988).The first class of water reducers was the lognosulfates derived from wood and paper industry ,but are now advantageosuly replaced by other synthetic sulphonates and polycarboxylates also known as SUPERPLASTICIZERS.

A. Admixture

Admixtures modify the properties of concrete or mortar to make them more suitable for the work at hand ,or for economy ,or for such other purposes as saving energy. Admixtures ensure quality of concrete during mixing ,transporting ,placing and curing .It increases workability ,accelerate setting ,reduce and prevent shrinkage ,reduces / modify bleeding ,increase strength ,decrease permeability ,reduce heat of hydration increase bond between concrete and steel,improve Impact and Abrasion resistance ,inhibit corrosion of steel and produce coloured concrete.

Admixtures work by one or more of the following actions:

- Chemical interaction with the cement hydration process ,causing acceleration/retardation of the rate of reaction of cement phases

- Adsorption onto cement surfaces causing better particle dispersion ( plasticizing or superplasticizing action)

- Affecting the surface tension of water resulting in increased plastic viscocity or mix cohesion.

- Introducing special chemicals into the body of hardened concrete that can affect specific properties such as corrosion susceptibility of embedded steel or water repellence.

The admixtures affect the properties of cementitious material between the time of mixing and hardnening by affecting water demand, change the stiffening rate ,change the air content and change the plastic viscosity i.e cohesion or resistance to bleed and segregation of the mix. Admixtures have increased both compressive strength and durability of concrete through their water/cement (w/c) reduction, hydrophobic effect ,increased density etc .This tremendously increased their use in the construction industry today.

There are two types of Admixtures, viz.,Chemical admixtures and Mineral admixtures .Accelerators ,Retarders, Water-reducing agents ,Super plasticizers, Air entraining agents etc .are commonly used chemical admixtures .Fly-ash Blast-furnace slag ,Silica fume and Rice husk Ash are examples of mineral admixtures.

B. Effect Of Chemical Admixture On Properties Of Concrete

Chemical admixtures are used to reduce the water cement ratio and to control the setting time while maintaining the flow ability of cement pastes apart from cement, water and aggregates. They are used to improve concrete quality, managebility, and acceleration and retardation of setting time. The properties that are improved are heat of hydration, accelerate or retard setting time, workability, water reduction dispersion, air entrainment etc.

A good number of researches were carried out to study the effect of chemical admixture on concrete properties. The effect of admixture on workability, compressive strength, split tensile strength, Young’s modulus has been studied to identify best chemical admixture.

- Material Properties: Here five different types of chemical admixtures were used viz one being water reducer and rest four being super plasticizer (SP1, SP2, SP3, SP4). All the type of chemical admixtures comply with ASTM C494. Crushed stone were used as coarse aggregate. Maximum size of aggregate being 19mm. River sand was used as fine aggregate. The physical properties of coarse and fine aggregate were determined as per ASTM guidelines. The cement contain 75% clinker and 25% mineral admixture including ground granulated blast furnaces slag, lime stone, fly ash and gypsum.

The figure below shows the gradations of course and fine aggregate satisfy ASTM C33 requirements.

The Chemical and physical properties of chemical admixtures, and there dosage ranges as recommended by the manufactures for the best performance are mentioned in table 1.

|

Chemical Admixture |

Composition |

Appearance |

Specific Gravity at 25° C |

Recommended dosage range ( % weight of cement) |

|

WR |

Lignosulfonate Based |

Dark Brown Liquid |

1.17 |

0.23-0.47 |

|

SP1 |

Sulfonated Naphthalene Polymer Based |

Dark Brown Liquid |

1.24 |

0.87-2.23 |

|

SP2 |

Poly carboxylic Ether based |

Light Brown Liquid |

1.05 |

0.42-1.26 |

|

SP3 |

Second Generation Poly carboxylic ether Polymer based |

Light Brown Liquid |

1.10 |

0.55-1.32 |

|

SP4 |

Organic Polymer Based |

Dark Brown Liquid |

1.1. |

0.71-1.31 |

2. Mixture Portion and Cases Studied: Three different types of concrete mixtures were prepared viz M1, M2 and M3 at an ambient temperature of 25° C ± 2° C. Mixtures were prepared using a laboratory mixer having a capacity of 75L. Each mixture was initially mixed for 5 min at a speed of 20rpm to ensure homogeneity and then at a speed of 6rpm to stimulate the mixing process of RMC in truck mixer. In order to conduct slump tests mixer was stopped at an interval of 15 min The mixing process was continued till the final sulmp became less than or equal to 2cm. Each M1 concrete mixture was prepared using the average of the maximum and minimum dosage of every chemical admixture recommended by respective manufacturer. While on the other hand M2 and M3 mixtures were prepared using the maximum recommended dosages of admixtures.

The details of different type of mixtures are present in below table

|

Mix Type |

Details |

|

M1 |

W/C = 0.40: s/a=0.40; C= 340kg/m3; average admixture dosage |

|

M2 |

W/C = 0.40: s/a=0.40; C= 340kg/m3; maximum admixture dosage |

|

M3 |

W/C = 0.40: s/a=0.40; C= 340kg/m3; maximum admixture dosage in 2 stages: 2/3 at the Beginning and 1/3 when slump ≤ 3cm |

3. Specimen Preparation and test Setup: All the concrete mixtures and chemical admixtures viz M1, M2 & M3 is subjected to prolonged mixing. Slump tests were done at an interval of 15min as per ASTM C143. The mixing process were stopped when mixture became ≤ 2cm and then poured into cylindrical mould to prepare cylindrical specimen of 200mm and 300mm. After casting specimen were cured for 24hrs by covering the cylindrical mould with wet clothes to prevent moisture loss. After 24hrs they were demoulded and then cured under water till the age of testing as per ASTM C31. These cylindrical specimens were tested for Young’s modulus, compressive strength and split tensile strength at 7 days, 28 days and 90 days respectively according to ASTM specifications.

Results:

- According to JSCE 2007 guidelines for normal weight RMC, the minimum slump requirement is 8cm at the place of unloading. Therefore the workability of each concrete mix was based on the time up to which the slump value was greater than 8cm. The more the time, the better the workability and vice versa.

- Fresh performances of concrete with super plasticizers were better in compression with water reducer.

- Chemical admixture remained workable for longer duration when the dosage of admixture was increased.

- The workability of fresh concrete decreased when s/a ration was increased from 0.40-0.45 (because of increase in the volume of fine particle with the increase of s/a ratio).

- For given W/C, the workability of concrete would increase with increase of cement content.

- Concrete with chemical admixtures result in higher compressive strength, Young’s moduli, split tensile strength as compared to the concrete without chemical admixture.

4. Effect of Mineral Admixture on Properties of Concrete: Mineral admixture improves the workability of fresh concrete. Workability is an important characteristics of fresh mortar or concrete. Some of the mineral admixtures used in concrete are fly ash, ground granulated blast furnace slag and silica fume. Each of them affect properties of concrete in different weather conditions.

A. Advantages of Mineral Admixtures

- Less cost

- Result in energy saving

- Improve workability

- Reduce alkali aggregate reaction

- Increase water tightness

- Increase strength

B.Disadvantages of Mineral Admixture

- It is more expansive and less effective

- It increases drying shrinkage

- It provides less resistance to sulfate attack

II. SUPERPLASTICIZERS

Superplasticizers (SP's) also known as high range water reducers are additives used in making high strength concrete. They allow reduction in water content by 30% or more and retard the curing of concrete.

Generally superplasticizers are classified as 1) Purified lignosulfonates , 2) Carboxylate synthetic polymers , 3) sul-fonated synthetic polymers 4) synthetic polymers with mixed cementitious materials

Superplasticizers are additions that allow a given degree of workability to be obtained at the reduced water/cement ratio. They have the effect of neutralizing the surface attractions between individual particles of the cement , causing them to form a less open structure, which therefore require less water to fill the spaces and provide fluidity to the paste. By decreasing the water/ cement ratio in this way , superplasticizers act to increase the strength of the cement product.

They produce extreme workablity flowing concrete and has the efficiency of dispersing fine grained particles like fly ash , ground granulated blast furnace slag and silica. These polymers are used as a tyoe of dispersants to improve the flow characteristics of suspensions and avoid particle segregation.

A. Experimental Studied Effect of Different Superplasticizers on the heat of Hydration of Cementitious Material.

An Experimental study conducted by Michal Matysik et al summarized below as:

Two sets of cement paste were prepared for the procedure:

The first set included naphthalene-sulphonate-based superplasticizer.

The second one included lignin-sulphonate-based superplasticizer.

We used cement CEM I 42, 5 R and w-c ratio w = 0, 38.

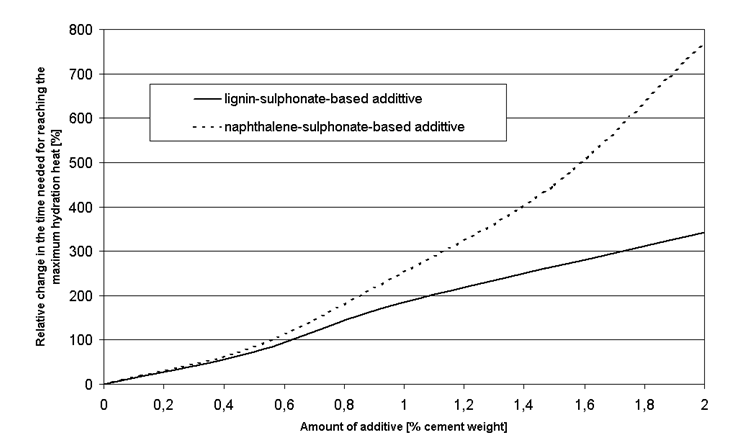

The graphs display the relative change in the maximum heat of hydration versus the additive amount and the relative change of the time needed to reach the maximum heat of hydration versus the additive amount for the two sets of cement pastes.

Figure 1: The relative change of the maximum heat of hydration versus the super- plasticizers amount used.

Figure 2: The relative change of the time needed to reach the maximum heat of hydration versus super-plasticizers amount used.

As we can see from the above graphs, the hydration process is influenced by both ligninsulphonate and naphthalene-sulphonate based super-plasticizers. Naphthalene-sulphonate-based superplasticizer extend in a greater extent the time needed to reach the maximum heat of hydration but lignin-sulphonate-based superplasticizer reduce pronouncedly the heat of hydration.

B. An Experimental Study Conducted by Qing Haung et al Summarized Below As

Experimental Programs

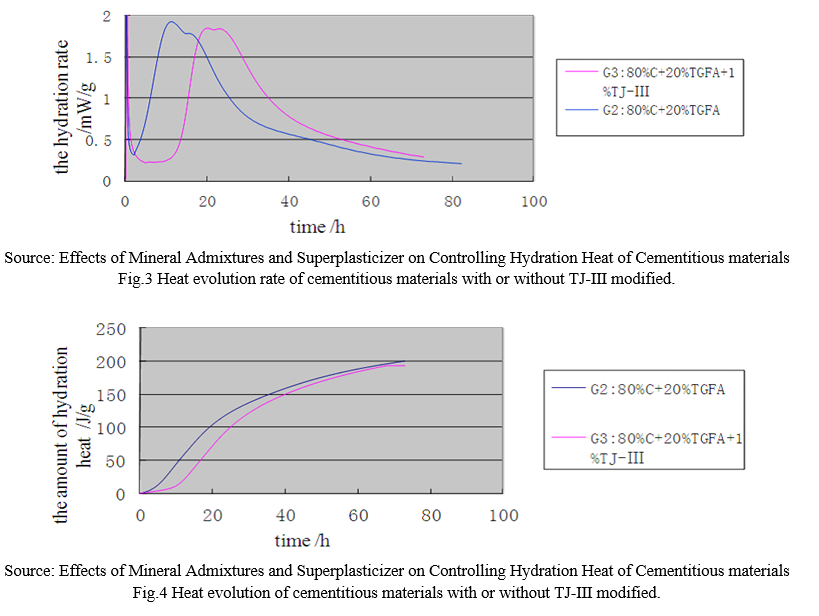

- Materials: The cementitious materials used for the experiment in this study consist of the Portland cement (P.O 42.5) which is produced by Gezhouba cement plant, the TJ-? superplasticizer.

C. Evaluation of the Effect of Superplasticizer

Fig.3 shows that TJ-? can increase the induction period and slowed the heat release operation. The exothermic peak of the cementitious material with TJ-? modified was attained 10h later than the cementitious material without TJ-? modified. And in Fig.4, shows the superplasticizer TJ-? can decrease the production of early hydration heat sharply. In terms of the results presented the fall percentage of the hydration heat was 74.1% after 10h setting time, but was only 2.17% after 72h, which implies that this superplasticizer (TJ-?) can minimize the heat of hydration mainly in the early times of the hydration.

Conclusion

The workability of each concrete mixture was based on the time up to which the slump value was greater than 8cm, therefore more the time, the better the workability. The workability of fresh concrete decreased when sand/aggregate ratio was incresead from 0.40-0.45 because of increase in the volume of fine particle with the increase of sand/aggregate ratio .For given water/cement ratio , the workability of concrete would increase with increase of cement content. Chemical admixtue remained workable for longer duration when the dosage of admixture was increased .Concrete with chemical admixtures result in higher compressive strength, Young\\\'s moduli, split tensile strength. The addition of superplasticizer can reduce the heat of hydration in the beginning and it was also seen that it can delay the occurence of exothermic peak, and lower the peak value of heat evolution. Moreover, it was seen that super plasticizer can also increase the induction period of the hydration, thus useful for controlling the early heat of hydration of the mixture.

References

[1] Academic editor : Jose M.Monzo ;Published(17 dec 2017) Tarik Uddin Mohammad, Tanvir Ahmad. [2] J.W Martin , in Materials for Engineering (third edition) ; 2006 [3] ACI 212.3R.16 [4] ACI Committe 212 2010 [5] Qing Huang ; 2013-01-11 [6] Michal Matysik ; 2015-04-29

Copyright

Copyright © 2022 Mehak Bashir, Zafira Nazir, Sharafoun Nisa, Sana Hameed, Sabree Ashraf, Snowber Yousuf. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET39230

Publish Date : 2021-12-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online